Manufacturing Solutions

Industrial Grade Solutions Built for Heavy Duty Material Handling

The AMRs, PowerPal and M3i series from Dane seamlessly integrate into your workplace, eliminating risks in industrial material handling and boosting employee productivity. Leading manufacturers use our solutions to move sub-assemblies and transport materials safely. With state-of-the-art technology and user-friendly controls, these devices enhance safety and productivity in manufacturing environments.

Autonomous Mobile Robots

Maximize Output, Minimize Risks, Improve Reliability

Dane Technologies is a leader in creatively addressing automation, ergonomic and logistic challenges in the workplace through innovative Autonomous Mobile Robots (AMRs).

Autonomous Inventory Robot (AiR)

Along with our software partner Bain Corp, Dane AiR revolutionizes retail and distribution center workplaces with advanced robotics and AI, boosting productivity and efficiency. With 37,000+ robots deployed coving 250 billion square feet, Dane AiR and BrainOS® lead in commercial public spaces. Its real-time data and innovative features enhance decision-making and operational oversight, ensuring a strong ROI. Embrace Dane AiR and BrainOS® for intelligent automation, reduced overhead, and transformative operational efficiency.

Quick Facts

- Enhanced productivity and efficiency

- Real-time inventory insights

- Reduced overhead costs

- Remote route generation and optimization

- Nimble and agile navigation

Vision Guided Vehicle (VGV) Tug

Easily implement autonomous technology by driving the VGV manually while the camera-based Co-Pilot system maps the environment, learning routes and waypoints. This creates a flexible, cost-effective VGV, eliminating traditional autonomous vehicle setup costs.

Quick Facts

- Self-Learns: Maps, Routes, & Waypoints

- Recognizes & Responds to People & Environment

- Automatic & Continuous Mapping System

- Touchscreen Interface Creates & Selects Routes

- Instant Transition Between Manual & Autonomous Modes

- Multiple Hitch Options

AutoDelivery Robot (ADR)

ADRs are designed for dynamic facilities needing flexible, easy-to-deploy solutions. These robots operate autonomously with obstacle avoidance capabilities, seamlessly integrating into workflows alongside human workers and existing equipment. They offer cost-effective deployment and are adaptable for various tasks, making them a valuable tool to enhance operational efficiency and responsiveness in modern warehouse environments.

Quick Facts

- Autonomous navigation with advanced sensors

- Customizable payload options for versatility

- Seamless integration with existing systems

- Scalable deployment across large facilities

- Eco-friendly operation with rechargeable batteries

PowerPal Series

The PowerPal series boosts productivity,safety, and maneuverability.

PowerPal Cart Mover (CM)

The PowerPal CM is rated for 18,400 lb (8,354 kg) and designed to pull industrial grade carts–increasing productivity, and reducing risk in the workplace. Tow trailers, roll cages, CC carts or anything on wheels without risk of strain or injury. Compact design, tiller steering and wide range of hitch options make the PowerPal Cart Mover the most flexible power pusher on the market.

Quick Facts

- 1.38 HP motor; 18,400 lb (8,354 kg) capacity

- Tiller Steering w/Optional Dual Mode

- Multiple battery & Hitch Options

- Ergonomic Design Prevents Injury

- Advanced Safety Features Including Automatic Dynamic Braking

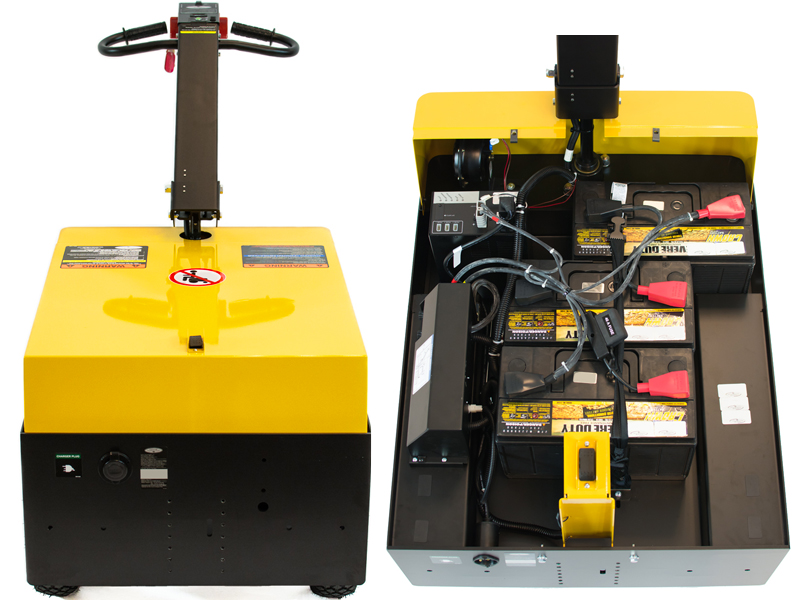

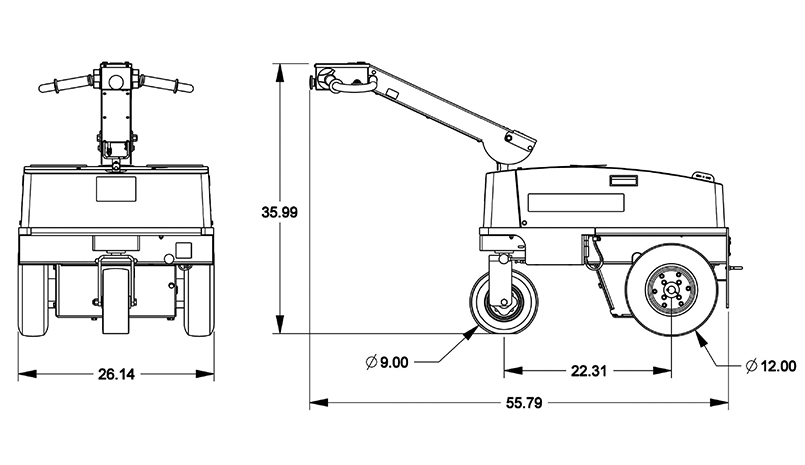

PowerPal Cart Mover (CM) HD

The PowerPal CM HD includes heavy duty upgrades & design features. Powered by a 1.75 HP motor, the PowerPal CM HD is rated to tow carts up to 20,000 lb (9,080 kg). Housed in a heavy-duty powder-coated steel body, the CM HD offers tiller steering with optional dual-mode control and 16 in. knobby-tread tires, for moving heavy vehicles, carts, or trailers.

Quick Facts

- 1.75 HP motor; 20,000 lb (9,080 kg) capacity

- Tiller Steering w/Optional Dual Mode

- Multiple battery & Hitch Options

- Ergonomic Design Prevents Injury

- Advanced Safety Features Including Automatic Dynamic Braking

M3i Series

The M3i Series efficiently moves heavy loads with ergonomic design and power-assisted strength.

M3i & M3i5

The M3i is ergonomically designed to increase capacity and minimize strain to the operator. The M3i platform allows for an optional 5th-wheel hitch package, the M3i5. Combining a 1.38 HP motor rated for pulling capacity of 18,400 lb (8,354 kg), a heavy-duty powder coated steel frame, and best in class controls and electronics the M3i and M3i5 deliver maximum control in moving large items and remarkable productivity and safety returns.

Quick Facts

- 1.28 HP motor; 18,400 lb (8,354 kg) capacity

- Optional 5th-Wheel Hitch for Maximum Control (M3i5)

- Solid-Swivel Caster Steering

- Multiple battery & Hitch Options

- Ergonomic Design Prevents Injury

- Advanced Safety Features Including Automatic Dynamic Braking

M3i & M3i5 HD

The M3i HD is the heavy-duty upgrade to the M3i. Combining a 1.75 HP motor rated to push/pull 20,000 lb (9,080 kg), 16 in knobby tread tires, a heavy-duty powder coated steel frame, and best in class controls and electronics, the M3i HD offers outstanding safety and productivity gains in a variety of workplaces. The M3i HD also allows for the 5th-wheel hitch package, the M3i5 HD for precise maneuvering of heavy wheeled loads.

Quick Facts

- 1.75 HP motor; 20,000 lb (9,080 kg) capacity

- Optional 5th-Wheel Hitch for Maximum Control (M3i5)

- Solid-Swivel Caster Steering

- Multiple battery & Hitch Options

- Ergonomic Design Prevents Injury

- Advanced Safety Features Including Automatic Dynamic Braking

Global Competition

By 2025, 1.8 billion people will join the global consuming class, pushing manufacturers to keep up. From 2000 to 2010, manufacturing value added grew from $5.7 trillion to $7.5 trillion (in 2000 dollars). However, rising wages in developing countries and a shrinking manufacturing sector in developed countries are eroding competitive advantages from outsourcing. Additionally, commodity prices are expected to rise 30%-80% by 2025. To stay competitive, manufacturers must cut costs, boost productivity from existing assets, and adopt new technologies that enhance productivity and deliver positive returns on investment.

Learn More

- Globally, online retail purchases totaled over $1.5T in 2015 and are projected to reach $3.4T in 2019.

- U.S. online retail sales in 2016 exceeded $290 billion, growing 14% over 2015.

- Online grocery sales reached $20B representing 4.3% of all grocery sales.

- FMI projects online grocery sales will account for up to 20% of all grocery sales by 2025. They project compound annual growth rates between 9-20%. At the top end of the range, that represents a 500% increase over the next decade.

Aging Workforce

The average age of manufacturing employees in developed countries is over 50, increasing the risk of musculoskeletal disorders (MSDs), work-related injuries, and fatigue. In the U.S., MSDs cost manufacturing employers over $100 million annually in direct compensation, with indirect costs adding 1.1-4 times more. Workers over 45 are 1.25-2 times more likely to suffer lost-work injuries due to MSDs than those under 30, and workers over 50 need twice as many recovery days. To remain competitive globally, manufacturers must leverage new methods and technologies to reduce preventable injuries and improve productivity.

Learn More

| Age Group | Average (MSD) Rates (per 10,000 FTE): |

|---|---|

| All Workers | 36.1 |

| Age 45-54 | 41.7 |

| Age 25-34 | 33.0 |

| Age 20-24 | 28.3 |

| Age 16-19 | 19.3 |

Distortion occurs in MSD rates for individuals 55-64 because average retirement age is 58

- 11 million manufacturing workers in the U.S.

- Average Rate of MSD (0.0036) * 11 million people = 39,600 incidences/yr

- 39,600 incidences * 9 days (avg. time lost) * 8 (hours/day) = 2,851,200 hours/yr

- 2,851,200 * $35.67 (avg. direct compensation/hr) = Direct Cost of MSD’s = $101,702,304/yr

Workplace Safety

Financial decision-makers see a $4.40 return for every $1 invested in workplace safety, a return that grows when productivity also increases. We specialize in ergologistics, merging workplace ergonomics with transportation logistics. Our solutions help manufacturing clients move sub-assemblies, transport raw materials, respond quickly to cleanup events, and position equipment and carts. Designed to mobilize your workforce, our solutions deliver exceptional safety and productivity returns in manufacturing environments.

Learn More

- Ergonomically designed power assist devices safely move 3- and 4-ton loads while reducing strain and risk to staff & employees

- Our portfolio of patented technologies deliver the most advanced safety and design features in the power-assist industry

- Our quality designed solutions deliver the lowest life cycle cost & greatest ROI of any in-class competitor

Shopping Cart Collection and Trolley Management

The QuicKART® M3 and M3 HD are the world’s first and most popular shopping cart and trolley retrieval solutions. Ergonomically designed, these solutions boost productivity, capacity, and employee morale while reducing strain-related injuries and property damage. In 2017, we introduced the QuicKART® M4, the 4th generation of cart retrieval, offering a value-engineered, cost-effective solution for cart management.

E-commerce Fulfillment and Stocking

The Smart:Drive and Smart:Rack are key components of the Smart:System, designed to enhance order picking and restocking efficiency. The Smart:Drive offers a compact power assist for store environments, while the Smart:Rack provides a configurable cart for order fulfillment and restocking. Additionally, the Smart:Stack pallet system allows easy placement of carts in warehouse racks, optimizing back room floor space.

Guest Experience

Our personal mobility scooters for retail shopping guests, the SmartKART and SKoot, offer comfort and durability with a focus on safety, capacity, and maneuverability. Developed in response to requests from our retail partners, the SmartKART is a high-performance motorized shopping scooter that reflects top brand quality and delivers an exceptional guest experience, exceeding expectations even in the most demanding retail environments.

Commercial Cleaning

The QuicKLEEN is our ergonomic, multipurpose ride-on janitorial cart, perfect for managing large, high-traffic retail environments. Delivering 50% productivity gains in commercial cleaning, QuicKLEEN allows your workforce to handle multiple tasks efficiently, reduces strain-related injuries, and broadens your labor pool.