Vision Guided Vehicle (VGV)

Streamlining Indoor Logistics with Autonomous Efficiency

The Dane VGV Autonomous Mobile Robot Tug (AMR) streamlines indoor material handling through autonomous transport. This autonomous solution, enhances productivity, reduces labor costs, and ensures safety with advanced sensor fusion navigation, easy integration, and powerful fleet management software. The Dane VGV is powered by Anantak software.

Adaptive Vision Mapping

The camera and 3D LiDAR based guidance system automatically maps the environment, learning routes and stations, resulting in flexible and easily implementation with operations supported by SiteView fleet management.

Autonomous Navigation for Complex Environments

Equipped with advanced obstacle detection, dynamic path planning, and real-time environmental awareness, the VGV safely navigates active facilities—avoiding people and equipment traffic.

Dual-Mode Control for Operational Flexibility

Switch between manual and autonomous modes with a single touch. Whether you need operator control or hands-free delivery, the VGV adapts to your workflow and facility demands in real time.

Heavy-Duty, Configurable, and Ready to Scale

Tow up to 8,000 lbs with industrial-grade durability, built-in safety features, and modular hitch and sensor options. Deploy in hours, operate 24/7, and scale across your facility without costly systems or integration delays.

Engineered for high-capacity material movement

- Tows up to 8,000 lbs. of carts, trailers, or racks

- Configurable hitches support a wide range of payloads

- Adaptive pathing accommodates route changes and workspace reconfiguration

- Failsafe stopping and obstacle avoidance built in

- Easy deployment—train and drive in under a day

- Designed for safety and uptime in 24/7 operations

Reduce Labor Costs and Manual Burden

Automating repetitive transport tasks frees up labor, reduces workplace strain, and supports consistent, hands-free operation across shifts.

Increase Throughput Without Adding Headcount

Tow more with less effort. VGV tugs operate safely in live environments to keep materials moving efficiently.

Scale Without Operational Complexity

VGV units are fleet-ready, software-connected, and designed to adapt to your workflow.

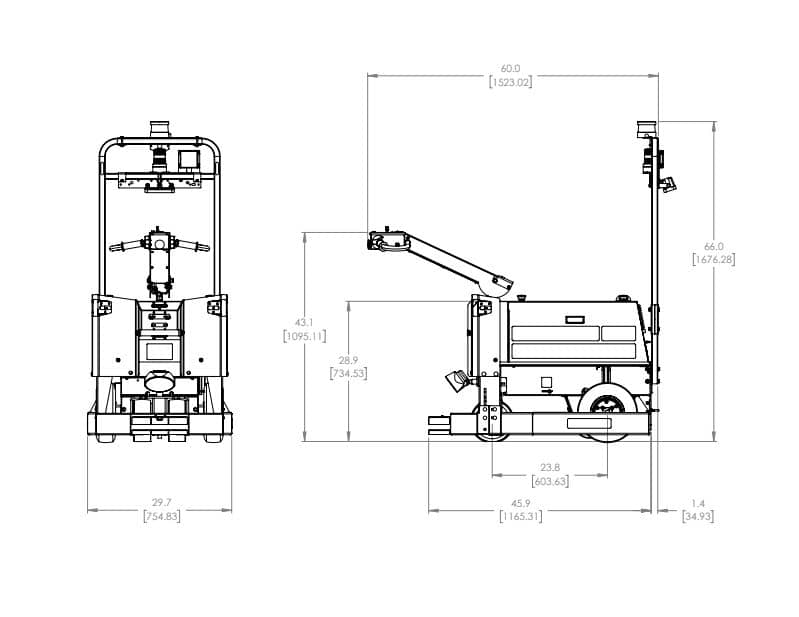

Solution Specifications

VGV Highlights

Specifications

| Feature | Feature |

|---|---|

| 950W Transaxle Power, Peak Power 1350W | (3) 12V, 230 ah Batteries for up to 12 hours run time |

| Ergonomic Controls | Cloud Connectivity -Either cellular or Wi-Fi |

| Safety Strobe, Red Path Light | Front and Side Guards, Camera Protection |

| Front and rear highly visible operation lights | On-Board Self-Diagnostics System |

| Safety Horn | On-Board Smart Charger, 120 V |

| 5 Emergency Stop Buttons | Guidance System by ANANTAK |

| Intuitive user interface - touch screen tablet | Anywhere Localization, no need for home marker |

| Instant Transition Between Manual & Autonomous | Coded Maintenance & Service Signals |