Industrial Tugs & Cart Pushers

Move Anything on Wheels with the PowerPal CM & CM HD

The PowerPal Cart Mover is a universal tug–designed to move anything on wheels in both commercial and industrial settings. Compact, highly maneuverable, with up to a 20,000 lb capacity, the PowerPal CM tugger can be used almost anywhere to eliminate safety risks and logistics challenges.

The PowerPal Cart Mover is ideal for moving large wheeled loads such as sub-assemblies, tow trailers, roll cages, CC carts, machine components, or any wheeled cart without risk of strain or injury. Compact design, tiller steering and wide range of hitch options make the PowerPal Cart Mover the most flexible power pusher on the market.

Contact Us View All Industrial Tugs Autonomous Tugs

PowerPal Cart Mover Series

PowerPal CM

PowerPal CM HD

Features

- Up to 20,000 lb Capacity*

- Flexible Hitching Options

- Tiller Steering & Compact Design

- 12 Hours Continuous Use on a Single Battery Charge

- Quiet Operation

- Advanced Safety Features

- Heavy Duty Upgrades Available with HD Model

*HD Weight Capacity Under Ideal Surface Conditions

Compare ModelsAutonomous Options

PowerPal CM Co-Pilot

Implement an automated workforce of self-learning, high capacity, adaptive towing vehicles for a fraction of the cost of other robotic or AGV solutions with camera-based, vision guided mapping. No need for complex systems or additional infrastructure—the PowerPal Co-Pilot starts work immediately, optimizing any environment where transport logistics are a part of the workflow.

- Camera-Based Guidance Transforms the PowerPal into an Adaptive Vision Guided Vehicle (VGV)

- Learns Routes & Waypoints in Manual Mode

- Co-Pilot Responds to Environment, Recognizing People & Avoiding Obstacles

- Touch-Button Transition Between Manual & Autonomous mode

- 6,000 lb Towing Capacity

- Secure, Cloud-Based Management System

Power Tugger Applications

The PowerPal CM is designed for almost any environment–whether you need to move a subassembly on a manufacturing floor, medical equipment in a hospital, or create an autonomous logistic system in your warehouse–the PowerPal CM series is designed to integrate seamlessly into any environment.

Autonomous Towing & Logistics

Implement self-guided technology into your business with the camera-based Co-Pilot guidance system. Vision guided vehicle (VGV) technology eliminates virtually all the set up costs associated with traditional SGV systems.

- Automate Almost Any Industrial Application of the PowerPaL

- Warehouse Tug & 3PL Logistics Mover

- Pick & Pack Logistics

- Consistant & Safe Transport of Goods

- Highly Adaptable Robotic Towing

- Unlimited Routes & Waypoints

- Wide Variety of Hitching Options

Industrial Grade Tug

The PowerPal CM is a versatile and powerful tug built to reduce the risk of material handling in industrial environments.

- Tow Heavy Carts & Trailers

- Move Subassemblies & Machine Components

- Pallet Mover

- Tow Roll Cages, & Specialized Trailers

- Airport & Transportation Center Logistics

- Military Logistics

- Luggage Cart Tugger

- Greenhouse Tug & CC Cart Mover

- Lumber & Construction Cart Tug

- Dumpster Mover

Specialized Indoor Towing

Intuitive controls, advanced safety features, & quiet operation make the PowerPal CM a flexible solution that can be used indoors, in professional environments, or alongside patients, pedestrians, and customers.

- Hospital & Healthcare Logistics

- Surgical Case Cart Mover & Medical Equipment Tug

- Tow Restocking Carts or Supply Carts

- Meal Cart Tug

- Convention Center & Resorts

- Linen Cart Tug

- Mail Cart Mover

- Retail & Stock Room

Industry Leading Features & Performance

Powerful Performance

- Standard 1.38 HP4-Pole (1000W) Continuous Duty Motor

- Heavy Duty 1.75 HP 4-Pole (1120W) Continuous Duty Motor

- 3 Group 31 Maintenance Free Deep Cycle 12 Volt Batteries

- On Board 16 amp @ 36VDC Smart Charging System (Includes Automatic Shut Off & Maintenance Charge Mode)

- Up to 12 Hours Continuous Use on a Single Charge

- Burst Mode Technology for Exceptional Performance

- Range of Hitching Options Connect to Any Wheeled Load

Best In Class Design Features & Controls

- Tiller Steering with Optional Dual Mode

- Protective Handlebar Design & Thumbwheel Throttle

- Programmable Speeds with Dual Speed Switch

- Battery Level Meter

- Key Switch Security

- Front Nudge Switch for Precise Positioning & Easy Hitching

- Warning Horn

- Robust Emergency Stop Button

- Advanced Safety Features Including Automatic Dynamic Braking

PowerPal CM Series Models

PowerPal CM

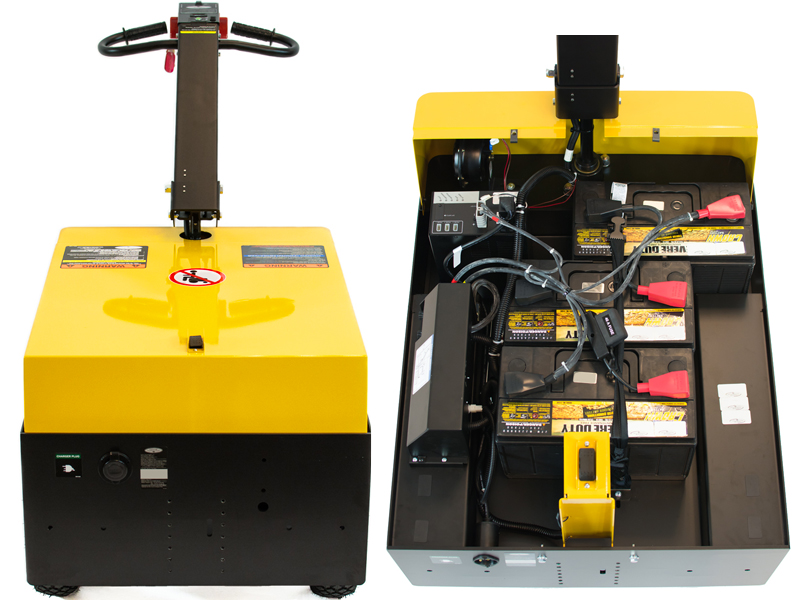

The standard model of the PowerPal Cart Mover is built to handle all logistics & material handling challenges safely and easily. Featuring ergonomic tiller steering, with optional dual-mode, & a range of hitching options to accommodate almost any wheeled load.

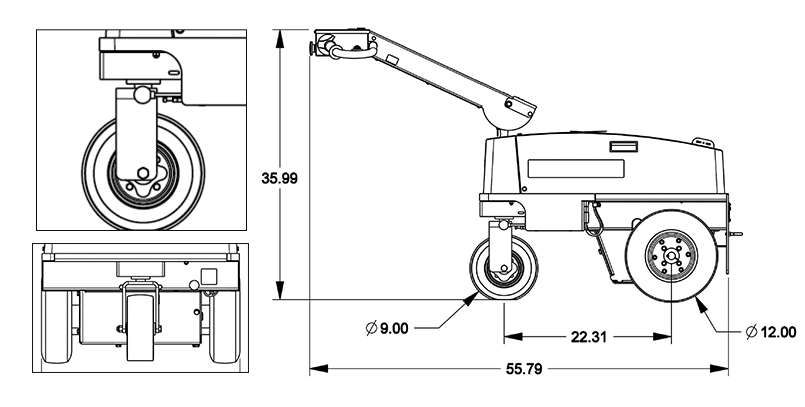

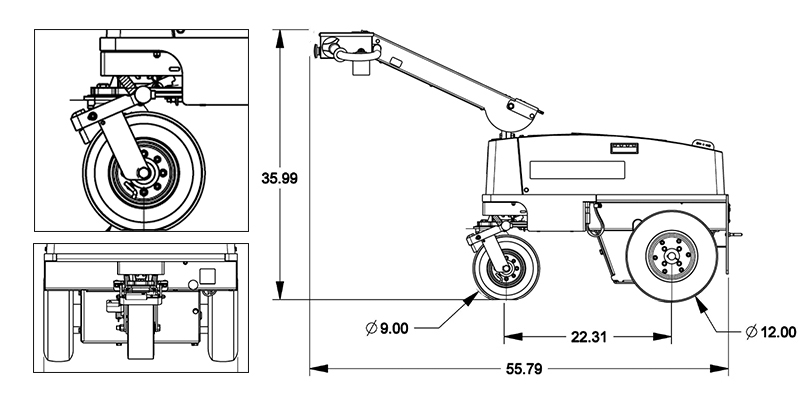

PowerPal CM HD

The PowerPaL HD is the high capacity Cart Mover designed with heavy duty upgrades to handle larger loads, while still featuring the same maneuverability & ergonomic design as the standard CM.

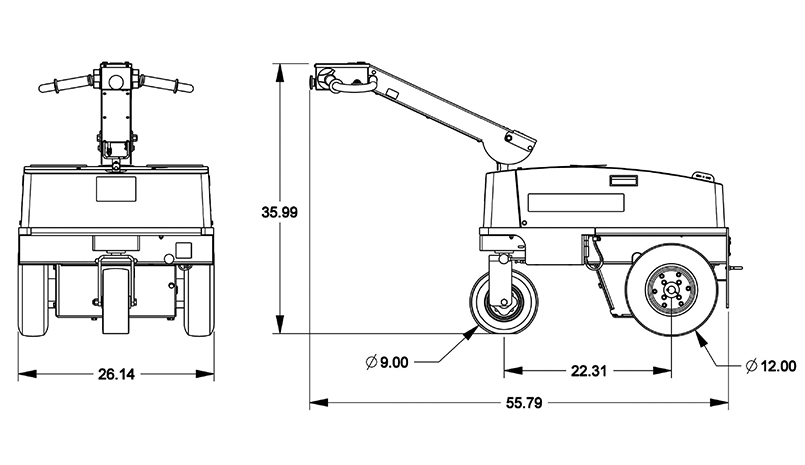

| Specification | PowerPAL CM | PowerPAL CM HD |

|

Motor |

Electric 1.38 HP 4-pole (1000W) |

Electric 1.75 HP 4-pole (1120W) |

|

Capacity |

18,400 lb (1,814 kg)*under ideal surface conditions |

20,000 lb (2,721 kg)*under ideal surface conditions |

|

Batteries |

(3) Group 31 Maintenance-Free |

(3) Group 31 Maintenance-Free |

|

Battery Life |

12 hours Continuous Output |

12 hours Continuous Output |

|

Transaxle Torque |

1,100 in.-lb Continuous, 1,400 in.-lb Peak |

1,820 in.-lb Continuous, 2,143 in.-lb Peak |

|

Tires |

Front: (2) 12 in. Solid Knobby Tread; Rear: 8.5 in. x 3.5 in. Solid Swivel Caster |

Front: (2) 16 in. Foam-Filled Knobby Tread; Rear: 8.5 in. x 3.5 in. Solid Swivel Caster |

|

Hood Material |

Welded Heavy Gauge Steel with Powder Coating |

Welded Heavy Gauge Steel with Powder Coating |

|

Throttle |

Hall-Effect Style, Forward/Reverse with Spring-Return to Neutral |

Hall-Effect Style, Forward/Reverse with Spring-Return to Neutral |

Tiller Steering Options

Standard Tiller Steering

Standard steering configuration of the PowerPal CM & CM HD, the operator steers the unit by turning the tiller, guiding the PowerPal in any direction in forward and reverse.

Dual Mode Tiller Steering

Dual mode steering option lets the operator choose between a steerable and fixed tiller. When in locked tiller mode the steering tiller is locked on centerline, and the operator is able to turn the whole machine, while the tiller wheel casters as needed. This feature gives the operator an extra degree of control while towing–especially in reverse.

Standard Features

| Item | Value | Description |

|---|---|---|

| Transaxle | Heavy duty, next generation & purpose-built for push/pull power assist | Superior bearings & gears; Torque: 1,100 in.-lb Continuous (6,160 cm-kg), 1,400 in.-lb Peak (7,840 cm-kg) |

| Ergonomic Steering Tiller with Optional Patented Multi-Lock | Ergonomic & intuitive steering tiller design; optional multi-lock locks tiller in place for safe & easy maneuverability in reverse | Allows greater maneuverability, & decreased turning radius for improved safety in materials handling |

| Motor | 1.38 HP continuous load motor | 18,400 lb (8,354 kg)* Load rating; efficient permanent magnet motor; long brush-life *under ideal surface conditions |

| Patented Burst Mode & Programmable Current Control | Patented feature allows for extra power during start-up | Reduced power after start-up; protects drive train, motor & extends battery life & run time |

| Hood/Chassis | Welded heavy gauge steel with powder coating | Materials are resistant to weather, rust, and cosmetic damage; frame is backed by Lifetime Warranty |

| Batteries | (3) Group 31 Maintenance-Free Deep Cycle | Long-life batteries; 12 hours continuous use on one charge |

| Smart Charging System | On Board 16 amp @ 36VDC series-balanced Smart Charger | Automatic shut off, maintenance charge mode, & battery life maximizer, 8 hrs required to achieve full charge |

| Electronics | Plug & play modular electronics, conformal coated molex connectors | Easy service & modular repairs, protects against moisture and vibration, easy access to connectors, spades, and lugs, no wire nuts, or soldered connections for easy maintenance |

| On-Board Self Diagnostics System | Coded maintenance & service signals | Eliminates unnecessary service trips & ensures the most uptime for your PowerPal |

| Easy-Service/Maintenance Design | Electronics housed in body, easy access, | Protected; motor & transaxle can be serviced without removing batteries |

| Patented Automatic Dynamic Braking System, Emergency Stop, and Parking Brake | Unit brakes to a stop when not under acceleration; parking brake automatically engages at rest; emergency stop button stops unit immediately | Enables safe handling & transport of heavy wheeled loads; prevents rollaway due to momentum or slope |

| Thumbwheel Throttle | Ergonomically designed, bidirectional | No mechanical parts; solid state position sensor; operator can control unit from either side |

| Control Panel Status Lights | Controller status on panel | Easier to operate, troubleshoot & repair |

| Tires | Drive: (2) 12 in. (30.5 cm) solid knobby tread; Steering: 8.5 x 3.5 in. (22 x 9 cm) foam-filled, tiller-mounted tire | Durable & low maintenance |

| Multiple Hitch Attachments | Allows for different configurations of use, load size, & trailer size | Attachments accommodate almost any wheeled load for power assisted moving of trailers, carts, trolleys, & roll cages. |

Safety Features

| Item | Value | Description |

|---|---|---|

| Certifications | Smart Charger: UL Standard 1564 | Highest industry standards for electrical & battery component compliance |

| Overload Fuse | Overload triggers automatic shutdown; 40 amp: easy reset | Protects motor, prevents unit overload |

| Emergency Stop Button | Intuitive placement, robust design, | Allow operator to stop unit quickly in case of emergency |

| Patented Automatic Dynamic Braking | Automatically decelerates PowerPal when not driving forward | Built in control & protection |

| Parking Brake | Automatically engages when PowerPal stops | Increased safety; prevents rollaway |

| Warning Horn | Button operation | Alerts those nearby |

| Battery Level Indicator | Monitors battery charge | Allows operator to monitor battery charge level |

| Protective Handlebar Design | Ergonomic handles reduce risk of wrist injury while handlebars protect hands & operational key switch | Reduces risk of injury, damage to throttle, & inadvertent operation |

| Programmable Speeds | Standard settings: Forward: 0 – 3.2 mph (0 – 5.1 kph); Reverse: 0 – 1.0 mph (0 – 1.6 kph) | Easy to use operation, ensures predictable control for operator |

Compare CM HD

| Specification | PowerPal CM | PowerPal CM HD |

|---|---|---|

| Motor | Electric 1.38 HP 4-pole (1000W) | Electric 1.75 HP 4-pole (1120W) |

| Capacity | 18,400 lb (1,814 kg)*under ideal surface conditions | 20,000 lb (2,721 kg)*under ideal surface conditions |

| Batteries | (3) Group 31 Maintenance-Free | (3) Group 31 Maintenance-Free |

| Battery Life | 12 hours Continuous Output | 12 hours Continuous Output |

| Transaxle Torque | 1,100 in-lb Continuous, 1,400 in-lb Peak | 1,820 in-lb Continuous, 2,143 in-lb Peak |

| Tires | Front: (2) 12 in. Solid Knobby Tread; Rear: 8.5 in. x 3.5 in Solid Swivel Caster | Front: (2) 16 in. Solid Knobby Tread; Rear: 8.5 in. x 3.5 in. Solid Swivel Caster |

Contact Us

Proven Experience: Key to Successful Implementation

Industry leading quality doesn’t stop with the design of our solutions – it extends to product rollout and post-sale support. Whether you manage one site or thousands, when you partner with us, we are putting 20 years of experience in tens of thousands of locations to work for you. We work together with you to understand the unique requirements of every worksite and collaboratively design your rollout strategy. With every sale, we provide training materials, a certified operators program, and best practices guidelines to ensure your team achieves your productivity and safety goals. Contact us to learn more.